Background

Over the course of the last 3 months there have been several finger incidents across all Divisions that have led to partial amputations. The following information provides a brief overview of the seriousness of some of the events and potential learnings that may assist with the prevention of similar events in the future.

Incident 1 – Burnie, Tasmania

An employee, engaged as a labourer at a glass and aluminium manufacturing facility, sustained an amputation injury to their ring and little finger whilst operating a radial arm saw to cut timber reveals to size.

Findings

- The radial arm saw did not have appropriate guarding in place

- The employee had not been formerly trained in the operation of the saw

- The Workplace Risk Assessment did not cover all activities performed onsite, including the safe operation of the saw

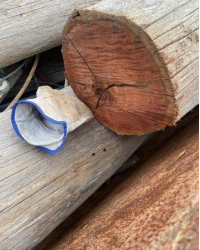

Incident 2 - Rottnest Island, Western Australia

An employee was in the process of moving timber power poles that had been cut up and placed in a skip bin, when one of the cut off poles moved unexpectedly, trapping their little finger between the pole below.

Findings

- The risk assessment process did not address the manual relocation of cut up power poles in the skip bin

- Hands free equipment was not available at the point of use

- The employee’s supporting hand was placed in a line of fire position.

Incident 3 – Telfer, Western Australia

A Supervisor on a shutdown at Telfer was in the process of transferring 20kg billets into the tray of a ute, when their little finger was caught between the tray and billet.

Findings

- The employee misjudged the height of the tray, leading to their finger being in a position that could be impacted.

What Can You Do To Reduce Your Risk

Job Planning – Consider the tools, equipment, protection and resources you need to minimise the risk of putting your hands in the line of fire.

Risk Assessment – Complete your pre-work risk assessment, every job every time to ensure specific hazards (ie contact with moving parts, crush, caught between) have been assessed and controlled. Where a change in the job arises, STOP and re-assess the risk.

Plant and Equipment – Plant and equipment must be fit for purpose. This includes guarding, cut-off switches, emergency stops etc. NEVER attempt to use a piece of plant that is not fit for purpose or inadequately guarded.

Communication – If working in a team (eg. Doing a team lift), keep the lines of communication open, especially when lowering objects to the ground and be mindful on where you place your hands / fingers.

Training and Competency – All staff to be suitably trained and competent in the operation of plant and equipment.

HSE Representative: Dan Hunt

Date of Issue: 19 July 2021