Project Description

Holcim’s Aotea Quay cement storage silos, located on Wellington’s busy waterfront, are crucial for the supply of materials to local construction projects. The silos were in dire need of a repaint, as it had been more than 20 years since the last maintenance. The preparation work on the main silo support frame was inadequate, resulting in large areas of peeling paint and visible rust stains. Additionally, the silos are located in a high-traffic zone, where cement trucks load and unload, and cruise ship tourist buses frequently pass through.

Holcim needed a solution that would allow them to accurately assess the condition of the silos without disrupting operations, while also adhering to stringent environmental and safety standards. Programmed’s advanced drone technology proved to be the perfect fit.

Project Solution

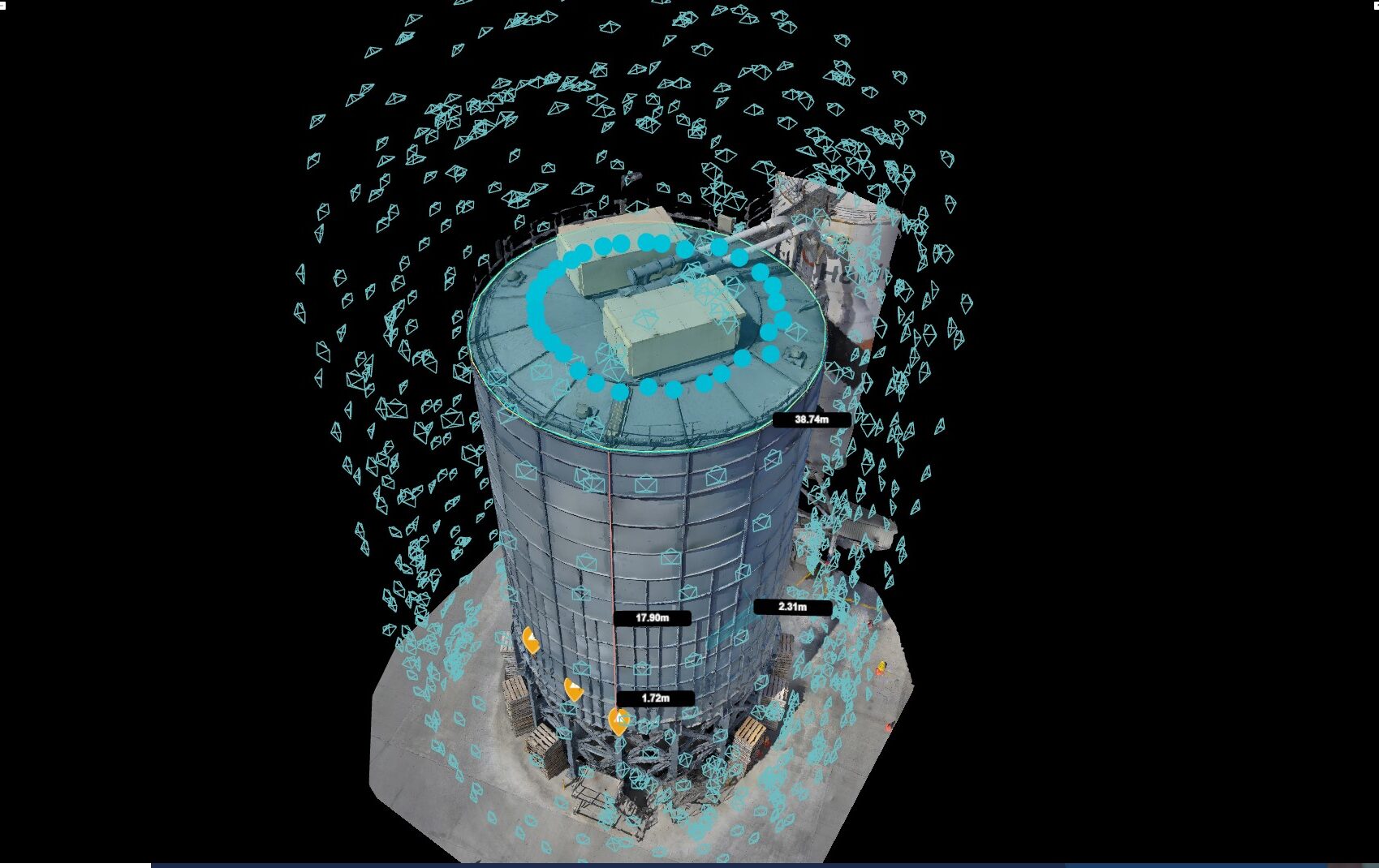

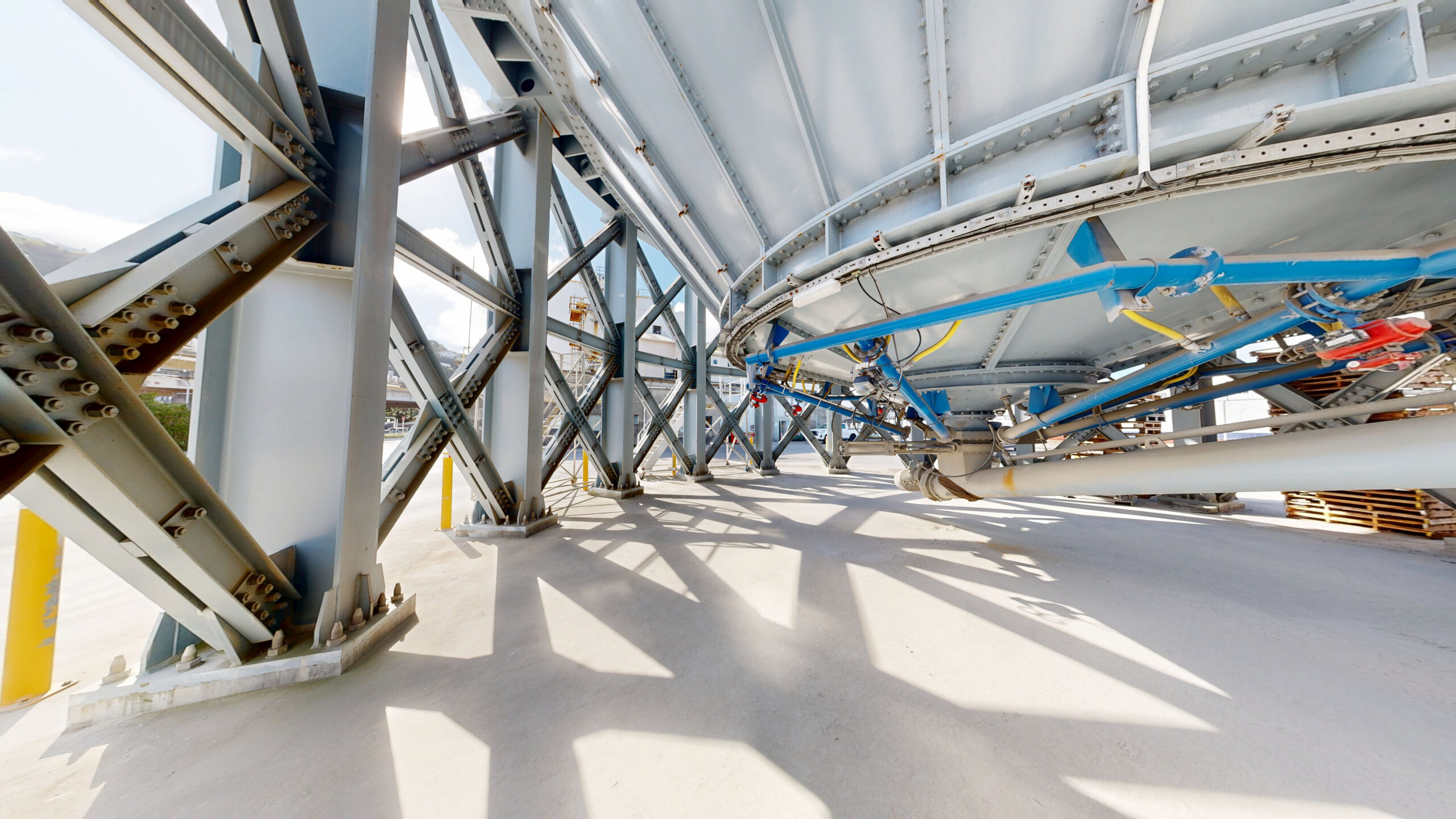

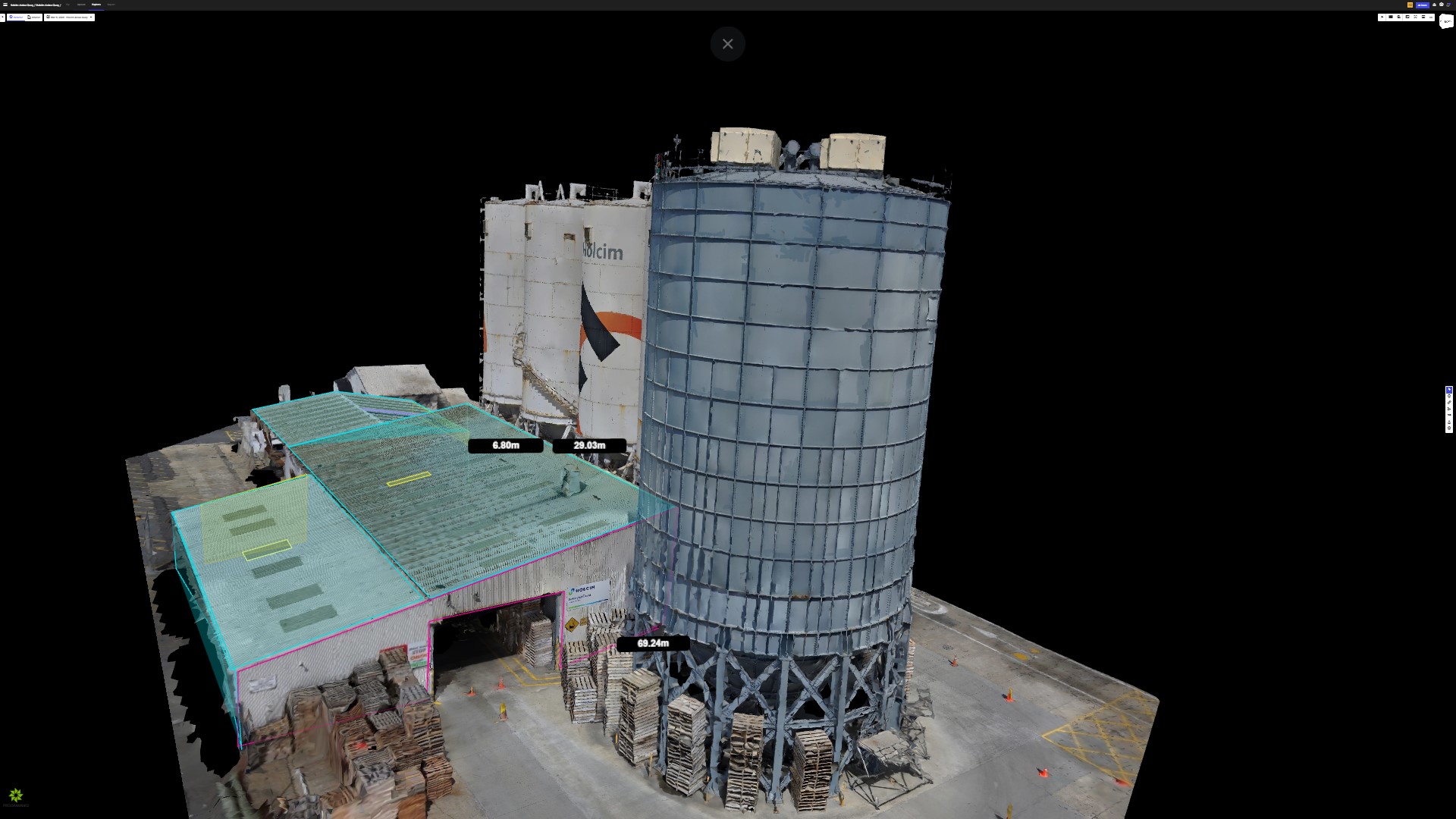

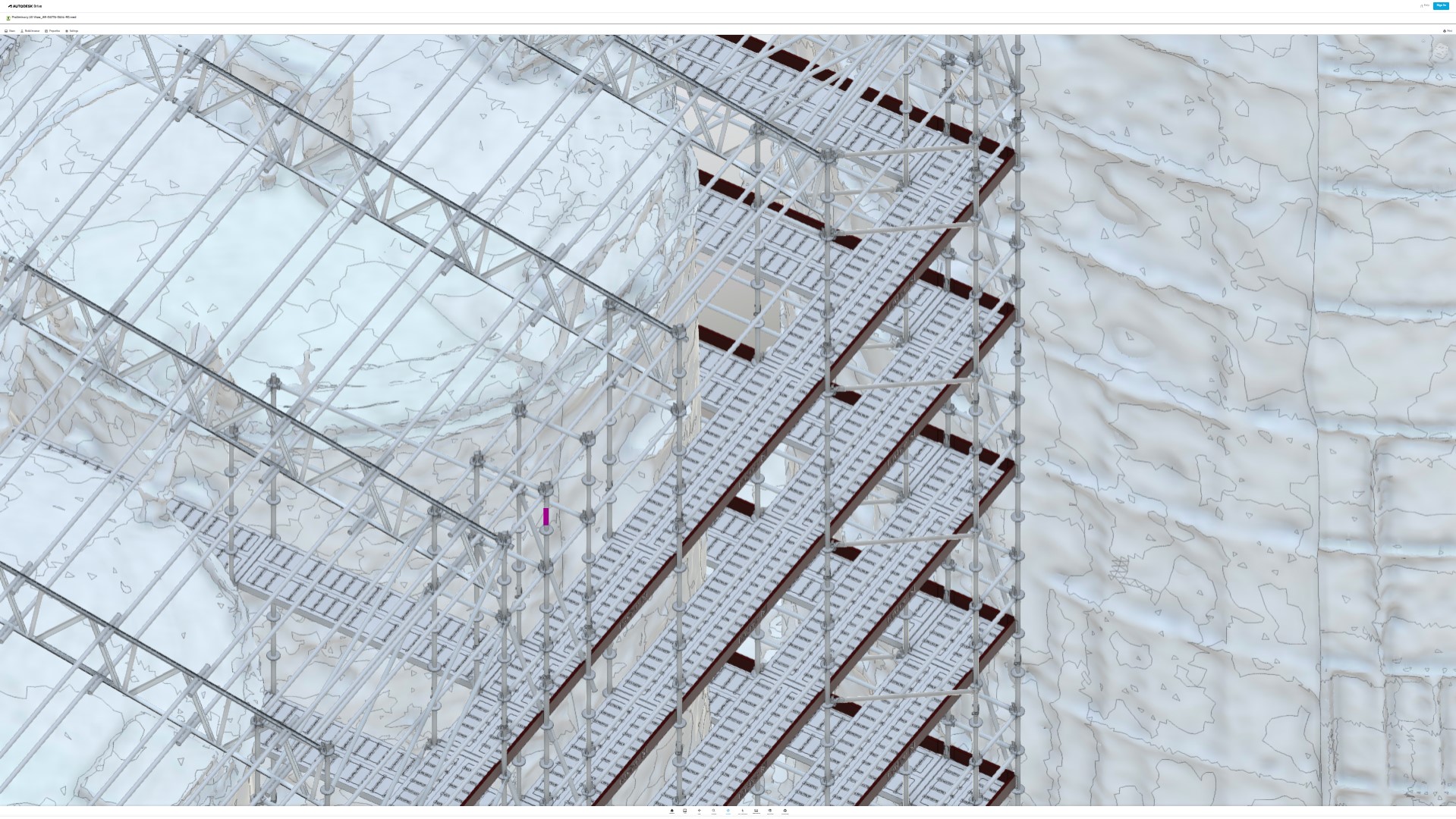

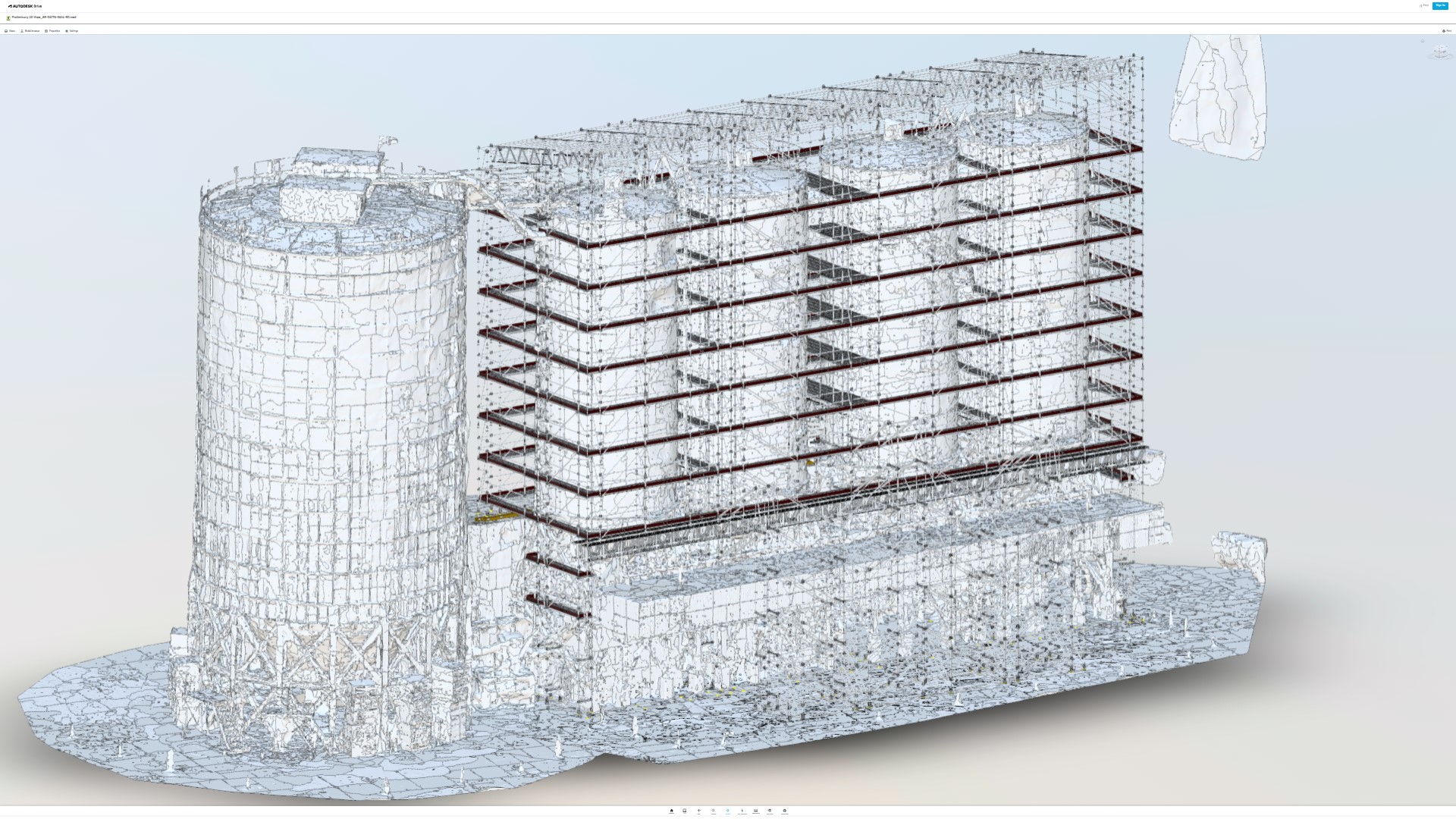

Programmed’s use of drone technology allowed for a comprehensive and detailed aerial survey of the silos. The high-resolution photos captured through our Drone Deploy system enabled us to zoom in and assess areas that were previously inaccessible. This provided a level of precision that was invaluable in determining the scope of the required work.

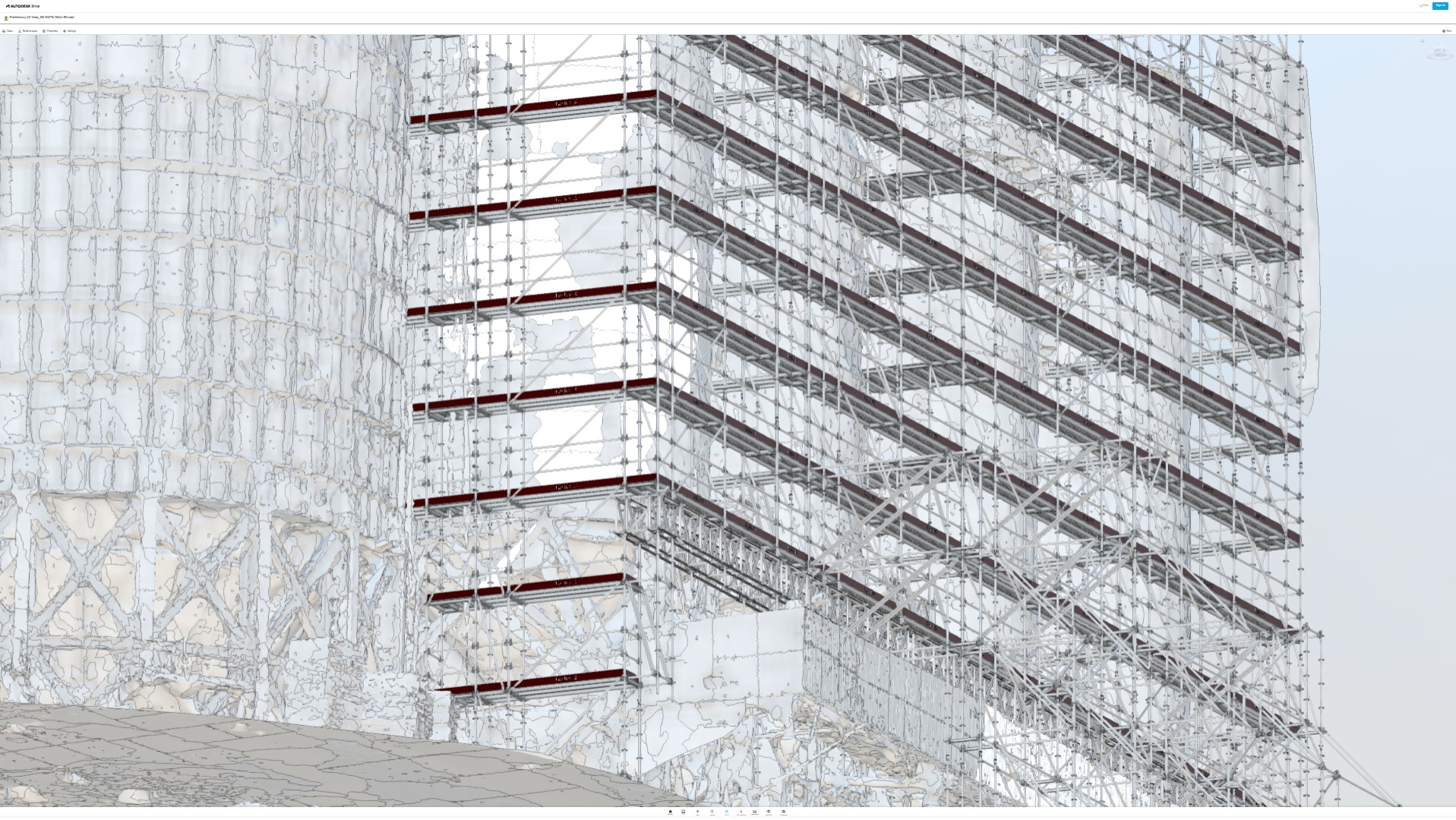

Furthermore, the access company used the data collected by the drone to generate a 3D model of the site. This model mapped out the layout of the scaffolding, while also highlighting areas where the structure extended into busy traffic zones, such as where cement trucks and buses operate. By having this 3D model readily available, we eliminated the need for an additional traffic management plan, and we will be able to plan and execute the project with pinpoint accuracy.

In terms of environmental responsibility, the use of drone technology will help us avoid unnecessary manual inspections and reduce the environmental impact of our operations. Additionally, the site will be fully wrapped to protect the silos from exposure to sea spray during the repainting process, and we will use innovative measures like boom socks and drainage mats to capture any loose particles and paint debris from entering the waterway and sea.

Project Outcome

The integration of drone technology will not only improve the accuracy and efficiency of the project, but it will also ensure Holcim could continue their operations without interruption. Thanks to the detailed insights provided by the drone, Holcim’s site staff will be able to carry out preliminary repairs before any of the painting processes begin and significantly reduce preparation time.

The outcome will include a rejuvenated facility with a fresh paint coating, and we can ensure the site is maintained and clean, with a professional appearance without disrupting ongoing truck movements or cruise ship-related traffic. The 3D modeling and precise measurements will ensure a seamless workflow, saving both time and resources. Furthermore, with the environmental safeguards put in place this will help minimise the impact of the work on the surrounding area.

Significant Areas of Value Add

- Drone Technology: Reduces the need for hazardous site visits and allows for more precise inspection, improving both safety and efficiency.

- Environmental Measures: We will implement a full environmental containment system to manage the removal of hazardous materials, which will include the use of boom socks and drainage systems to capture and contain contaminants from entering the waterway and sea.

- Cost Savings: The ability to conduct remote inspections using drone technology can save time and costs by eliminating the need for additional site visits and thus reducing the overall project duration.

Key Differences in Post-Completion Condition

post-completion, the silos will not only be visually refreshed with a new paint job, but the ongoing condition of the site will also be significantly improved. The thorough inspection process will ensure that any structural issues will be addressed before painting, and the environmental containment system will ensure that there will be no unintended impacts on the surrounding area.

- Digital Asset Capture

- Innovation

- Painting

- Property Services

- Technology